This page contains affiliate links.

In this article, I will explain the appeal and benefits of the Snapmaker, a multi-functional 3D printer that can perform 3D printing, laser processing, and CNC processing in one machine, to those who are considering introducing a 3D printer but would also like to try laser processing and CNC processing, based on my experience of purchasing and using the Snapmaker Artisan.

Snapmaker official website

What is Snapmaker?

The Snapmaker is a multi-functional 3D printer that can perform three functions in one: 3D printing, laser processing, and CNC machining.

It was launched in 2016 by the Chinese company Snapmaker and is currently

– Multi-function 3D printers Snapmaker 2.0 and Artisan

・Snapmaker J1 with 3D printer function only

・Snapmaker RAY with laser processing function only

There are several series released.

Below is the official SnapMaker Artisan introduction video.

[Snapmaker device lineup]

Snapmaker’s main product lineup is summarized in the table below.

| Model name | Standard Features | price |

|---|---|---|

| Snapmaker 2.0 A350T | 3D Printer Laser processing CNC Machining | From $1,349 |

| Snapmaker Artisan | 3D Printer Laser processing CNC Machining | From $3,499 |

| Snapmaker J1s | 3D Printer Only | From $1,479 |

| Snapmaker RAY | Laser processing only | From $1699 |

For a detailed comparison table, please see the official website. Compare Snapmaker Machines Please see.

[Snapmaker overview and features]

The Snapmaker is modular, with interchangeable tool heads and work plates for different functions.

The Snapmaker has a modular design, with interchangeable tool heads and work plates for different functions.

The Snapmaker Artisan in particular allows you to easily replace the head and plate.

Snapmaker 2.0 Quick swap kit now available for A350 (optional)

The Snapmaker 2.0 A350 also used to have a hard time replacing the work plate, but now Quick Swap Kit is on sale.

The reason I chose the Artisan instead of the A350 is because replacing this plate seemed like it would be a difficult task.

In addition to the standard tool heads, there are several optional modules available for upgrade.

Also, modules are compatible across different product series, though not all of them.

For standard modules and available options for each series,

The official website mentioned earlier Compare Snapmaker Machines is easy to understand.

Snapmaker is an assembly kit

The Snapmaker is an assembly kit, so once the product arrives, Build it yourself It is necessary.

In my case, assembly It took about seven days However, if you like making things, you will probably enjoy the time.

The tools required for assembly are included, so you do not need to purchase them separately.

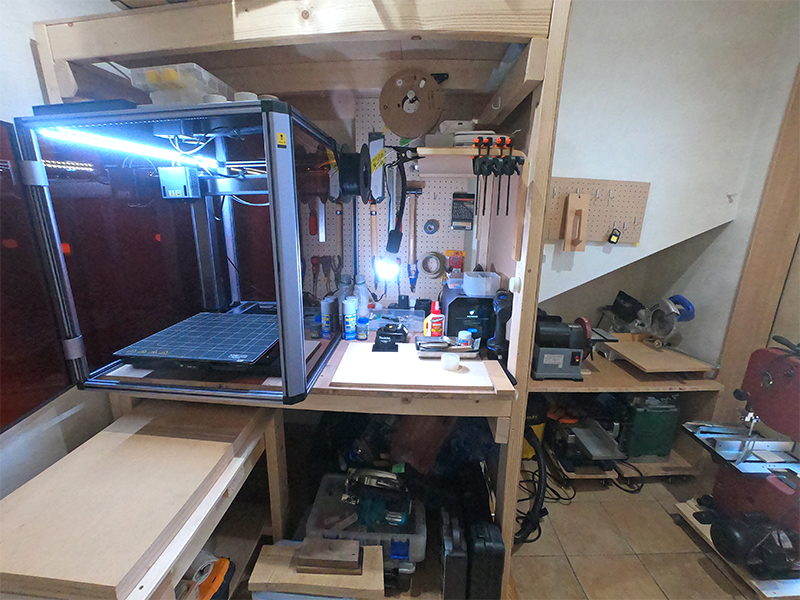

Please note that you will need a lot of space to assemble it, and once assembled, it will probably be difficult to carry it by yourself (it was impossible for me).

So Plan assembly and installation location in advance It is necessary.

Here is a digest video of me assembling the Snapmaker Artisan.

A seven-day process has been condensed into five minutes. I hope you can get a feel for the assembly process.

Dedicated Enclosure

The napmaker comes with an enclosure (a box-shaped case that covers the entire unit).

It comes standard with the Artisan and is optional with the Snapmaker 2.0.

The enclosure has the following benefits:

- Odor prevention and exhaust control

- Dust collection

- Noise control

- Stable 3D printing

- Safety considerations

These are explained in detail in this article.

https://lab.marchcreate.com/snapmaker_enclosure

Genuine manufacturer processing software provided free of charge

Snapmaker has Snapmaker Luban ” genuine manufacturer processing software will be provided free of charge.

However, with Snapmaker Luban alone, you can output using a 3D printer. 3D data itself cannot be created so please be careful.

I will explain using the flow I use (see the diagram below).

- The shape data is AUTODESK Fusion360 Created with (exported in 3MF format)

- Import 3MF data into Snapmaker Luban, set various settings, create G-code data, and check with simulation

- Import the G-code data into Snapmaker and start 3D printing

*The 3D printed item in the image above is originally made of PLA material, but has been sprayed with a gray primer.

I have only used the above flow, but it can be integrated not only with Luban but also with the following third-party software.

Ultimaker Cura

OrcaSlicer

PrusaSlicer

LightBurn

AUTODESK Fusion 360

About OrcaSlicer

On the official Snapmaker website Snapmaker Orca Beta has been released.

More information Snapmaker WIKI Third-Party Software Please see.

For more details, please see this article.

https://lab.marchcreate.com/snapmaker_slicer

About the end mills used with the CNC module

The Snapmaker Artisan comes with three types of end mills as standard. You can also use end mills with shank diameters of 0.5 to 6.35 mm or less that are compatible with ER11 collets. For more details, see this article.

https://lab.marchcreate.com/snapmaker_endmill

What types of materials can be processed?

wood

Solid wood (beech, walnut, oak)

MDF

carbon

metal

Brass H62

Aluminum 6061

More information Official website support page (Supported Materials section) Please see.

What filaments can be used?

In addition to the original filament sold by Snapmaker, third-party filaments can also be used.

https://lab.marchcreate.com/snapmaker_filaments

[Pros and Cons of Snapmaker]

[Benefits of Snapmaker]

- The biggest feature is 3D printing, laser processing, and CNC processing all in one machine That’s it

- The three functions can be changed by rearranging the modules. Only one installation space is required

- Dedicated software that can create the G-code data required for processing Snapmaker Luban Developed by Snapmaker and available for free

- Since it is an assembly kit, it is beneficial for people who enjoy assembling things themselves.

- Module compatibility across product series

- There are also plenty of options available, such as a high-power laser module and a 4-axis CNC rotary module.

Disadvantages of Snapmaker

- Compared to buying a 3D printer alone Price is high

- It requires self-assembly, which is a disadvantage for those who are not good at it.

- Since functions can be changed by rearranging modules, two functions cannot be used at the same time.

- Although it only requires one installation space, the dimensions including the enclosure are W665 mm x D943 mm x H705 mm.

A certain amount of space is required to install the controller.

It is quite heavy, so after assembly It’s difficult to move alone Please note that the weight of the item itself was not measured, but the total weight of the package was 67.95kg. - The dedicated software Snapmaker Luban alone is not enough. 3D shape data itself cannot be created Therefore, it is necessary to link with other software.

- There is no Japanese distributor So if you want to buy it, you have to buy it from the official online shop.

- Similarly, there is no Japanese distributor, so you will need to contact Snapmaker yourself to get support.

Snapmaker Artisan Specs Table (Official Site)

[Examples of use]

My use case

I’ll give you an example of my use case.

Case 1: Making a jig using a 3D printer

We created hose adapters to connect the dust collector to each processing machine.

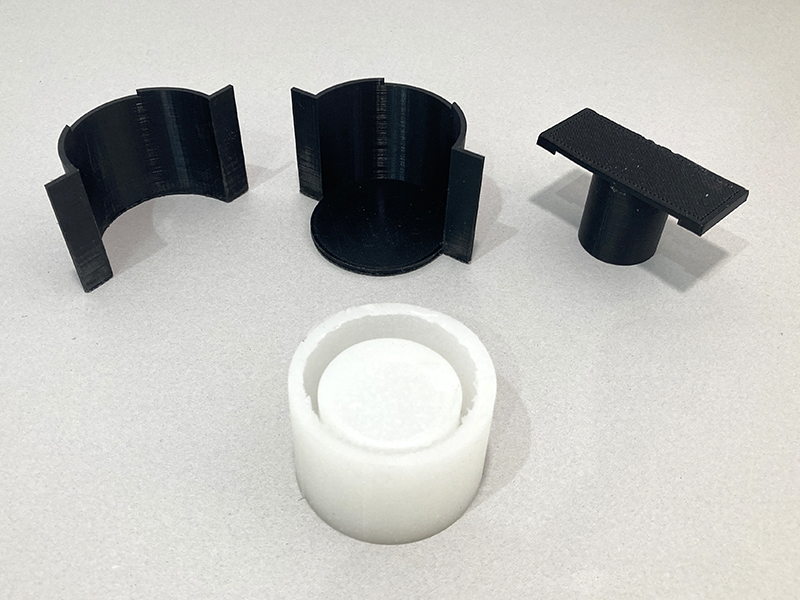

Case 2: Creating a silicon mold using a 3D printer

We created a mold to make silicon molds, which are necessary for manufacturing with cement materials.

The 3D print above in black PLA is the mold used to make a silicone mold, and the white one below is the silicone mold made from that mold.

By the way, this candle pot was made by pouring cement into this silicone mold.

The black walnut lid was also CNC machined using the Snapmaker.

Case 3: Tray production using CNC machining

The tray was made by CNC machining solid white oak.

There are still marks from the end mill on this part, so it’s still not quite complete.

Laser processing is more difficult to set up than 3D printing or CNC processing, so we are currently in the process of trial and error.

If I can make something to show, I’ll let you know.

Use cases from users around the world

See examples of how users around the world are using the service here Case Study Page Please see.

[About purchasing Snapmaker]

How to buy Snapmaker

As of December 2024, there is no distributor in Japan. Buy directly from the official website It will be.

You can also request a quote in advance.

Request a quote on the official website

You can also check everything that is included in the product package when you purchase the Artisan series from the following page.

IN THE BOX

My purchasing experience

I ordered on February 19, 2023 and it arrived on May 17, 2023.

I hadn’t heard anything on the way, so I inquired about the situation, and A few days after the inquiry, the status will be “in delivery”, and about 3 weeks later It was delivered to.

I thought maybe it had been forgotten, but I don’t know for sure.

The model I purchased was the Snapmaker Artisan Standard model.The cost was $2,899

Sales happen from time to time

As of December 2024, a Christmas sale is being held.

Artisan Premium Standard (40W laser model) for $2,599.00 instead of $3,499.00 $900 off It is as follows.

Register as a user on the official website Subscribe to receive sale information So,

If you want to make a purchase at a discount, please register.

Register as a user and receive special benefits (maybe even receive filament)

This was also done when I purchased it, but if you register as a user on the official website, You will receive an additional filament.

It seems that PETG filament is currently available.

[About Snapmaker Support]

What kind of support does Snapmaker offer?

Official support provided by Snapmaker includes:

- Email Support

- Official website chatbot

- Support Center

- FAQ page

- Facebook Owner Community

- forum

The technical information is as follows:

Snapmaker Warranty

Snapmaker is Free 1 year warranty after purchase There is.

There is also a paid support service called “Snapmaker Care” that will handle repairs and replacements after the warranty period.

For details on deadlines and applicable parts, Official page Please see.

Summary: Is Snapmaker a good buy?

I have explained the appeal and benefits of Snapmaker based on my experience purchasing and using it.

If you have read this far, I assume you are considering introducing a 3D printer, including Snapmaker.

In conclusion, I would like to answer the question: Is Snapmaker worth buying?

As I said, I bought it so I thought it was worth buying.

The basis for the decision is, after purchase,

- Will it expand my world of craftsmanship?

- Can I use it with confidence?

- Are you satisfied with the price?

I think this is the key point.

1. Will my world of craftsmanship expand?

This is what I want to make Can it be made with Snapmaker? I think that’s the point.

We encourage everyone to check the official website in advance for information on materials that can be processed, types of filament, and working space.

You can also get an idea of what can be created by looking at examples of work created by users around the world.

In my case, My first priority is to do CNC woodworking. It was stated as such.

When it comes to CNC woodworking, it is common to purchase an NC router, but there are several options:

・ORIGINALMIND KitMill MOC900

・Avalontech ArtCNC Assembly Kit

・Shaper Tools Shaper Origin

・Make your own NC router

I gave up on the Shaper Origin, which I wanted the most, because I couldn’t buy it in Japan. I tried to make an NC router myself, but I gave up due to lack of knowledge.

I was considering the ORIGINALMIND MOC900, but I wanted to try something else. Creating a jig with a 3D printer That was it.

We considered purchasing a 3D printer in addition to the MOC900, but the introduction costs would be high and the installation space would be large.

I came across Snapmaker, which solved all of those problems at once. I was also interested in laser processing, so it was like killing three birds with one stone.

2. Is it safe to use?

I was worried that it was not made in Japan, that its durability was unknown, and that the manufacturer would go out of business after I had made the purchase.

I decided to trust that they have been steadily upgrading their products since the first product of 2016.

3. Are you satisfied with the price?

The Snapmaker Artisan was a pricey purchase at around 400,000 yen, but considering that even the MOC900 costs over 600,000 yen, it’s not that expensive.

By being able to perform 3D printing, laser processing, and CNC processing in one machine, The expansion of the world of manufacturing I felt that this was the biggest benefit.

One more thing to add is that Snapmaker is a cool tool. I’m excited to use it This is also a big factor for me.

So for me, purchasing Snapmaker was the best decision I have made at the moment.

If circumstances change, I might also buy a CNC machine or a 3D printer. (I definitely want a Shaper Origin someday…)

This is how it is set up in my work space (entrance workshop).

Although tool selection can be a difficult task, it is also one of the most enjoyable aspects of manufacturing.

If you can choose the right tool for you, you will enjoy making things even more.

We hope this article will be helpful to you in selecting the right tools.